Overview

Chisholm Machinery is a provider of engineered equipment solutions to North American food processors. We are partnered with a select group of machinery manufacturers, each recognized as leaders in their field. Chisholm's core market is fruit and vegetable processors that manufacture chilled, fresh, frozen, or canned products. In addition, our equipment lines extend into the pharmaceutical, petrochemical, personal care, paint and other consumer packaged goods.

Capabilities

Depending on our customer's needs, we have the resources to provide a full range of services from simple sourcing of a single machine for an existing production line, up to complex integrated line solutions. CMS capabilities encompass line design, line layout drawings, equipment installation, and training. Our aftermarket parts and service staff are available to keep our equipment operating 24/7. We conduct a daily border crossing to accelerate customs clearance and reduce shipping time.

Expertise

In order to provide a higher level of service to our customers, each member of our sales team is a specialist in processing or packaging machinery solutions.

Processing - we provide a full line of processing solutions through our exclusive best-in-class suppliers complemented by other specific equipment partners depending upon the application. We have extensive experience in fruits and vegetables, dairy, protein, and snack foods. Equipment offerings include:

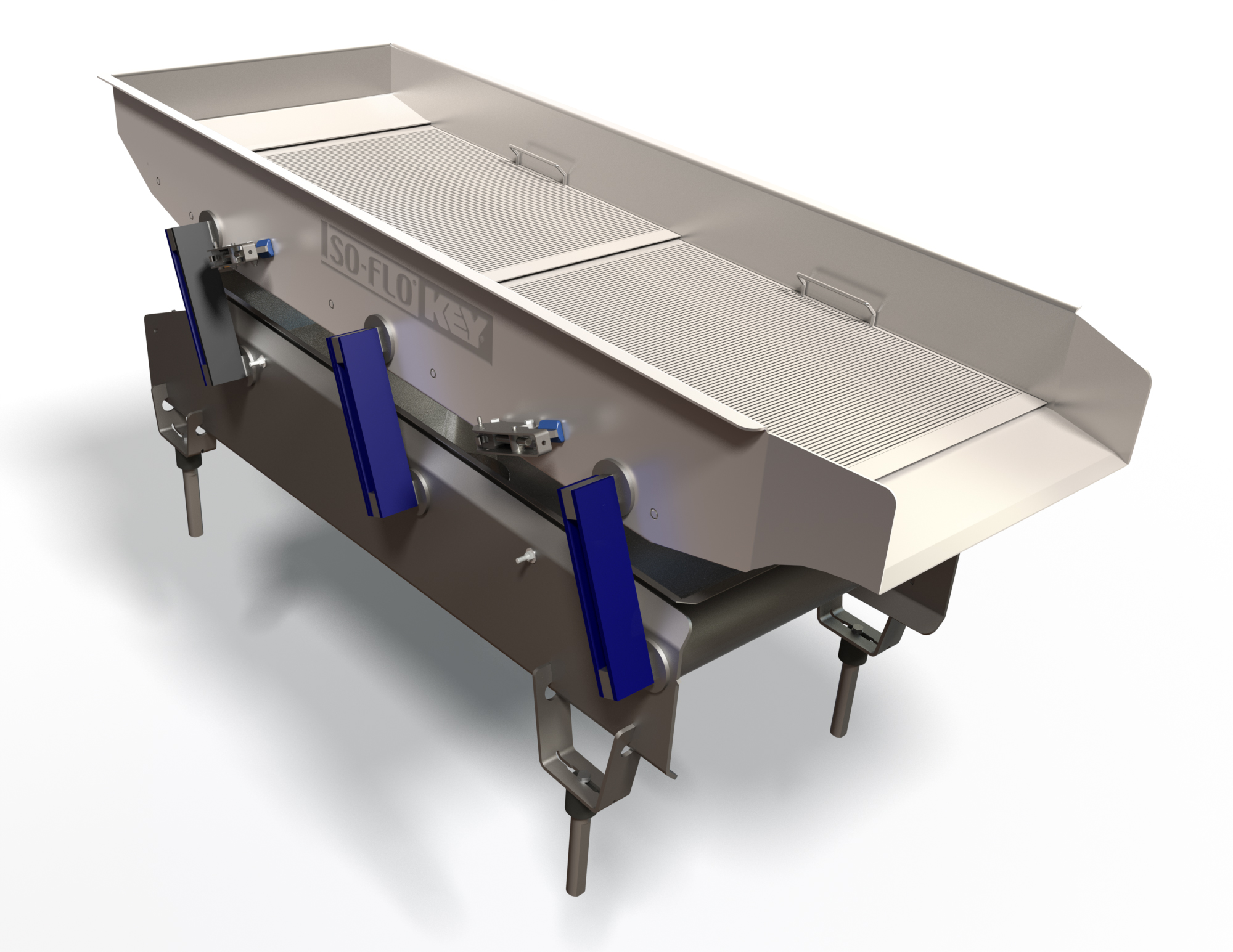

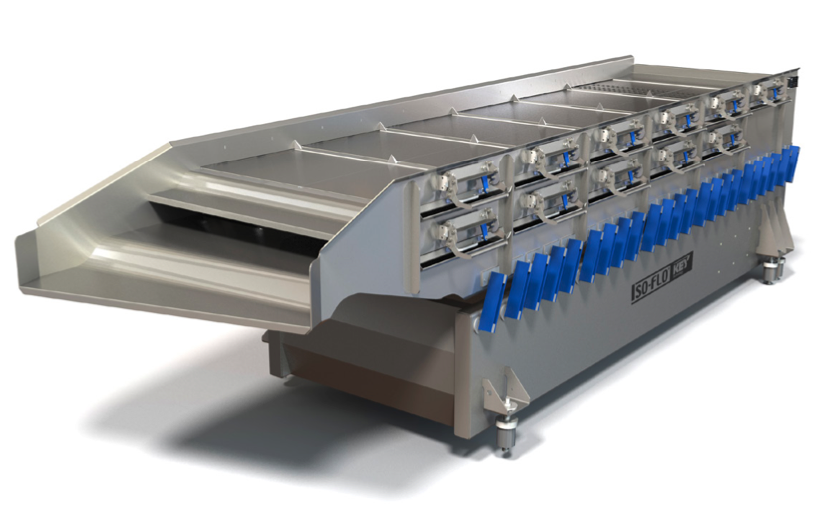

material handling - vibratory conveyors, screw conveyors, belt conveyors, bucket elevators

thermal processing - blanchers, cookers, coolers

peeling - abrasive, knife, steam

grading - roller sizers, vibratory screen, rotary drum

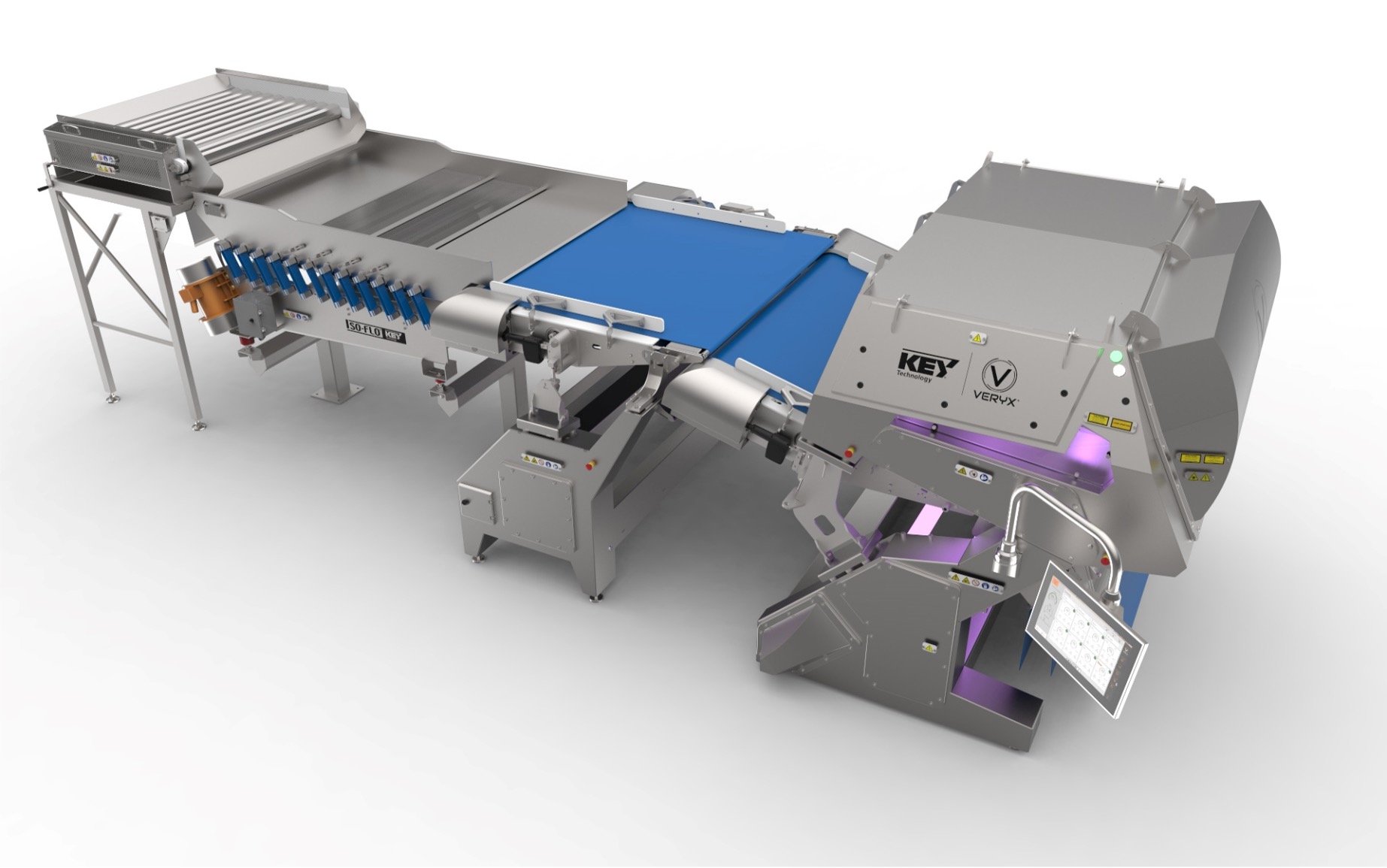

optical sorting - automatic removal of product defects and foreign material

size reduction - slicers, dicers, shredders, mills

Packaging - we provide a full line of packaging solutions through our exclusive best-in-class suppliers complemented by other specific equipment partners depending upon the application. We routinely augment existing packaging line equipment with targeted equipment selections to provide production improvements that directly impact your cost of goods. Today, more than ever, you need to be the lowest cost producer. We understand that and devise ways to get you there. Typical projects can include any combination of the following:

depalletizers

rotary fillers

seamers, cappers, closers

vertical form fill seal baggers

premade pouch baggers

stick pack and sachet

labelers

cartoning, bundling or tray/case packing

palletizing, including case conveyor, pallet wrappers, and pallet conveyor

History

Chisholm Machinery is a multi-generational family-owned company with origins in the early 20th century. Chisholm Engineering was established in Niagara Falls, Canada in 1932, with a vision to provide equipment automation solutions to the burgeoning North American food processing sector. Chisholm Machinery Solutions was incorporated in 1962 and continued expanding as a manufacturer’s representative with new OEM partnerships. Growth continued with second and third generation ownership leading the business into the 21st century. Ownership is now shifting to the fourth generation, with further growth and expansion into full-service aftermarket support well underway.